#Neri labeller code

The unique code identifies and makes it possible to track each carton.Ī camera then verifies both the codes and the readable data. The first operation to be performed after the cartons have been positioned is that of applying the vignette on the upper panel of the cartons then, the unique 2D code (Datamatrix) and the corresponding human readable data are printed on the side flaps and sometimes on the upper panel. By integrating the load cell into the toothed belt system of the BL A420 CW, it is able to verify the position of the cartons at all times: if the weight is correct, the product undergoes the subsequent processes (serialization, marking and sealing), then it is sent to the next machine if on the other hand the weight is not correct, the subsequent processes are skipped and the carton is rejected, according to the “Fail Safe” operating logic. The function of the timing device is to set the cartons at the correct distance apart its special feature is that it is synchronised with the speed of the whole conveyance system and there is no need for any size change-over adjustments.Ī load cell is fully integrated into the stepper conveyance system and is able to check the weight of each carton. A patented timing device positions and sets the cartons apart correctly on the toothed belts with adjustable opening, which also prevent slipping. The cartons are fed and accumulated in-line on the inlet belt to ensure a continuous flow of products, even at high speeds. The machine can process up to 400 cartons per minute. This solution is much more compact than the classic solution (where the weighing unit is coupled in-line) and than the version of main competitors of the market, who offer solutions having weighing units with their own independent conveyance system.

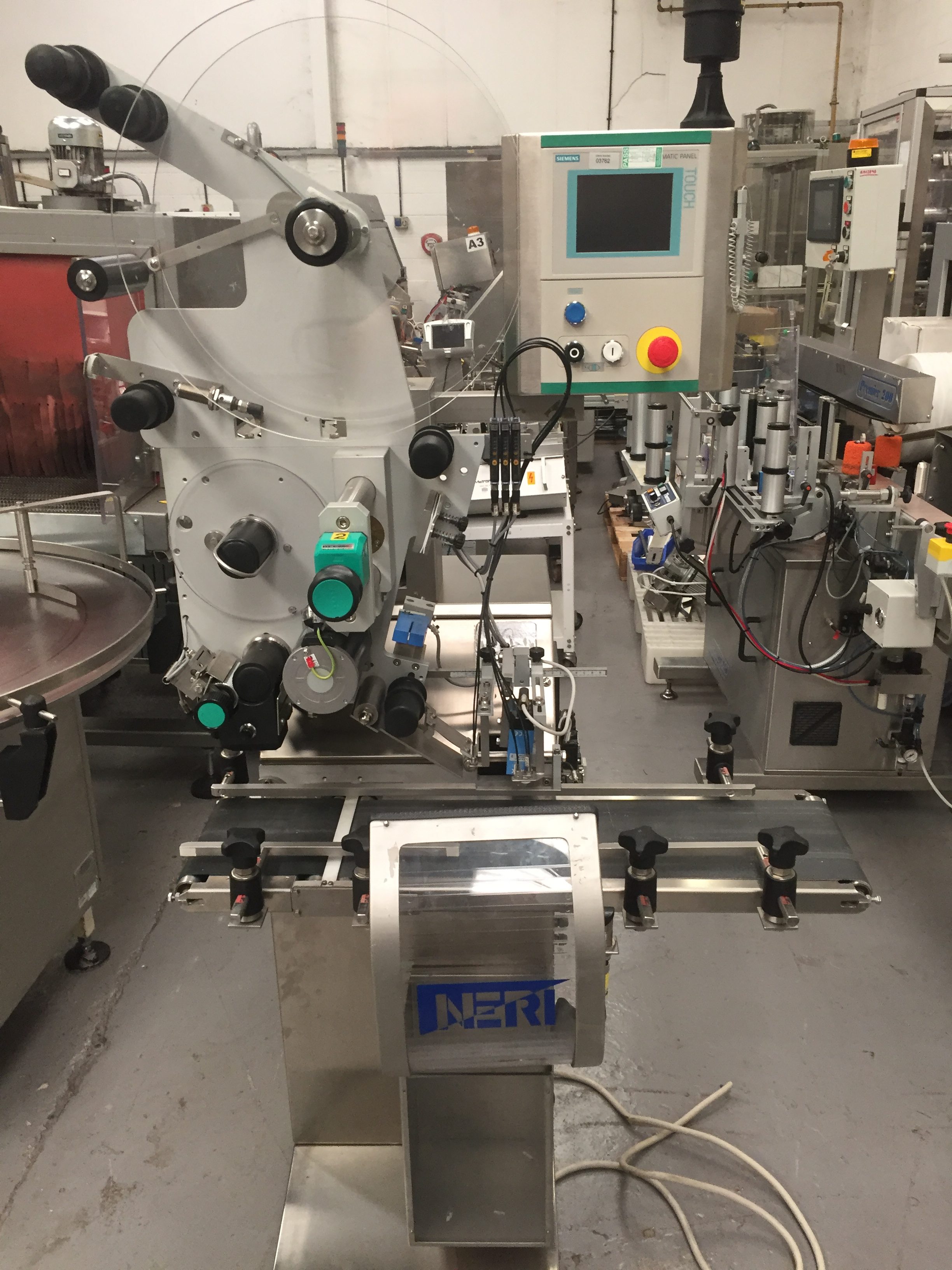

The model exhibited has a load cell fully integrated into the stepper conveyance system. Please note that this description may have been translated automatically.At Interpack, customers and professionals will be able to take a look at the new labeller BL A420 CW for Track and Trace requirements developed by Neri, the branch of the Marchesini Group specialises in carton labelling and tracking machines. Label reel maximum diameter 400mm, roll core 45mm to 75mm diameter

Label size range from 8 x 15mm up to 30 x 60mm Minimum load control at the inlet and maximum load control at the outletĬarton size range from 20 x 15 x 70mm up to 180 x 120 x 200mm

Automatic label changing system with set-up by keyboard and possibility to memorize different label sizes. Automatic work speed synchronization of motors. Label dispensing with stepping motor drive. Mechanical timing device to dispense cartons on the main toothed conveyor belts. Twin horizontal conveyor belt for products bunching at in-feed. Upper conveyor belt to keep carton stable during tamper evident seals application Positive transport of cartons with toothed belts. Easy access from behind to electrical and mechanical parts Electrical cabinet on machine board, Siemens S7-300 PLC controller with HMI touch screen

Labelling machine balcony construction stainless steel executed. Neri BL400 VTE tamper-evident labeller for the application 2 self-adhesive tamper-evident seals on the closure points of formed cartons and 1 vignette/bolini label or similar on the upper face of the carton.

0 kommentar(er)

0 kommentar(er)